Universal motor

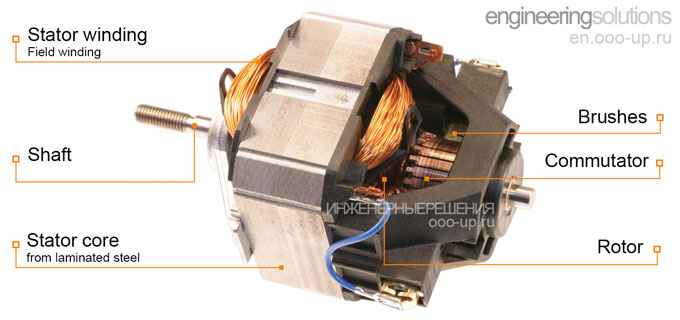

Construction of universal motor

The construction of the universal brushed motor does not have any fundamental differences from the construction of the wound field brushed DC motor, except that the entire magnetic system (both the stator and the rotor) has a laminated structure and the field winding is sectioned. The laminated structure of both the stator and the rotor is due to the fact that, when operating on alternating current, alternating magnetic fluxes penetrate them, causing significant magnetic losses.

Sectioning of the field winding is caused by the need to change the number of turns of the field winding in order to approximate the operating characteristics when the electric motor is operating from AC and DC power grids [2].

Universal brushed motor can be performed with a series, shunt and separately excitation.

Currently, universal brushed motors make only with series wound.

Working principle of universal motor

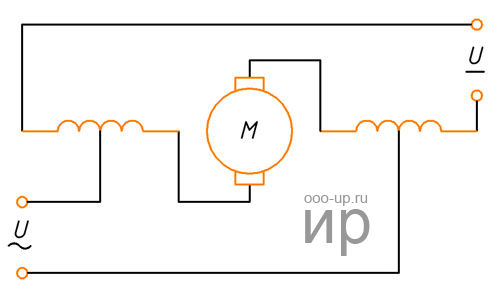

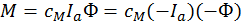

The ability of the universal motor to operate from the AC power grid is explained by the fact that when the polarity of the applied voltage changes, the directions of the currents in the armature winding and in the field winding change. In this case, a change in the polarity of the stator poles practically coincides with a change in the direction of the current in the armature winding. As a result, the direction of the electromagnetic torque does not change:

,

,

- where M is electromagnetic torque, N∙m,

- cM is constant coefficient determined by motor design parameters,

- Ia is current in the armature winding, A,

- Ф is main magnetic flux, Wb.

As the universal motor is used a series wound brushed motor, in which the armature current is also the excitation current, which provides an almost simultaneous change in the direction of the current in the armature winding Iа and the excitation magnetic flux Ф when transiting from the positive half-cycle of the alternating voltage to the negative one.

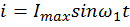

If the motor is connected to the mains of a sinusoidal alternating current, then the armature current Ia and the magnetic flux Ф will vary sinusoidally:

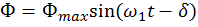

,

,

- where i is current, A,

- Imax is current amplitude, A,

- ω1 is frequency, rad/s.

,

,

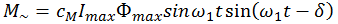

- where Фmax is the maximum value of magnetic flux, Wb,

- δ is the phase shift angle between the excitation current and the magnetic flux, due to the magnetic losses in the motor, rad.

From here we get the formula of the electromagnetic torque of series wound commutator motor, swiched in the network of sinusoidal alternating current, Nm:

.

.

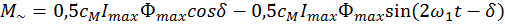

After conversion:

.

.

The first part of the expression is the constant component of the electromagnetic torque Mc, and the second part is the variable component of this torque Mv, varying in time with a frequency equal to twice the frequency of the supply voltage.

Thus, the resulting electromagnetic torque is fluctuating when the motor is running on AC power. Pulsations of the electromagnetic torque practically do not disturb the operation of the motor. This is explained by the fact that with a significant frequency of pulsations of the electromagnetic torque ( ) and a large moment of inertia of the armature the rotation of the latter turns out to be uniform.

) and a large moment of inertia of the armature the rotation of the latter turns out to be uniform.

Features of the universal motor

The efficiency of a universal motor when it is running on AC power is lower than when it is running on DC power. Another disadvantage of the universal motor is the severe switching conditions that cause intense arcing at the commutator when the motor is connected in the AC power grid. This disadvantage is explained by the presence of a transformer coupling between the field and the armature windings, which leads to the induction of the transformer EMF in the switched sections, which impairs the switching process in the motor.

The presence of the brush-commutator unit is the cause of a number of disadvantages of universal brushed motors, especially when operating on alternating current (arcing at the commutator, radio interference, increased noise, low reliability). However, at a supply voltage frequency of f = 50 Hz, these motors allow to obtain a rotational speed of up to 10,000 rpm and more, which is impossible to achieve for asynchronous and synchronous motors with a direct connection to the mains 50 Hz (the highest synchronous rotational speed at f = 50 Hz is equal to 3000 rpm) [3].

Applications of the universal motor

Due to the fact that a universal motor can have a high rotational speed when operating from a single-phase AC power grid without using additional converter devices, it has been widely used in household appliances such as vacuum cleaners, blenders, hair dryers, etc. Also, a universal electric motor is widely used in tools such as drills and power screwdrivers.

Due to the fact that the rotation speed of the universal motor is easily regulated by changing the magnitude of the supply voltage, it was previously widely used in washing machines. Now, thanks to the development of converter technology, brushless electric motors (PMSM, SCIM) are gaining wider use, whose rotational speed is regulated by varying the frequency of the supply voltage.

- GOST 27471-87 Rotating electrical machines. Terms and definitions.

- E.V.Armensky, G.B.Falk. Electric micromachines. 2nd edition.: Educational book for electrical engineering specialties of universities. - Moscow: 1975.

- M.M.Katsman. Electrical machines and electric drive of automatic devices: A textbook for electrical engineering technical schools. - Moscow: 1987.